Yield Impacts of Pod Shattering

- Yield loss from pod shattering can be subdivided into two components: pre-harvest loss from pod shattering that occurs in the field prior to harvest, and gathering loss that results from pods that shatter at the header during harvest.

- Extension agricultural engineers suggest that good harvest practices can reduce losses to near 3%, or only 1 to 2 bu/acre. However, delayed harvest or poorly adjusted equipment can result in losses of 10% or more.

- Yield losses can be calculated by counting seeds on the ground. Every 4 beans/ft2 corresponds to a yield loss of

~1 bu/acre.

Varietal Differences

Genetic Basis of Resistance to Pod Shattering

- Soybean varieties have genotypic differences in their resistance to pod shattering.

- Research has shown that resistance to pod shattering in soybean is a qualitative heritable trait (Caviness, 1969) controlled by multiple genes (Carpenter and Fehr, 1986; Tukamuhabwa et al., 2000).

- Physical characteristics of the pods, including pod length, pod wall thickness, and lignification of the cells along the suture lines of the pod valves influence resistance to shattering (Dong et al., 2014; Krisnawati and Adie, 2017)

Rating of Pioneer® Brand Soybean Varieties

- Pioneer brand soybean varieties are rated on a 1 to 9 scale for their resistance to shattering.

- 9 = Excellent tolerance to shattering

- 1 = Poor tolerance to shattering

- There ratings are based on data collected over multiple locations and years in field experiments managed to induce shattering

Factors that can Influence Pod Shattering

Environmental Conditions

- Drought conditions during pod development can increase the risk of pod shattering, a phenomenon that was widely observed during the 2012 drought.

- Drought conditions during pod development result in weak pod sutures more prone to splitting, particularly when the pods and beans are re-wet by rainfall following maturity.

- Drought stress effects on pod shatter can be exacerbated by infestations of two-spotted spider mites (Tetranychus urticae), which can compound plant stress and accelerate senescence (Ostlie and Potter, 2012).

- High temperatures at maturity can increase shattering (Bara et al., 2013).

- Late-season hail can damage pods and cause shattering (Figure 1).

Figure 1. A soybean pod that has been split open as a result of hail damage at the R7 growth stage (beginning maturity).

Insect Damage

- Pod feeding from insect pests such as bean leaf beetles and grasshoppers can damage pods resulting in seed loss (Figure 2).

Delayed Harvest

- The risk of yield losses from pod shattering becomes greater when harvest is delayed more than ~10 days beyond maturity.

- Shattering losses can increase significantly when soybean seed moisture drops below 11%.

- Repeated wetting/drying cycles between soybean maturity and harvest can cause pods to split and drop seed.

Figure 2. Soybean pod damaged by bean leaf beetles and/or grasshoppers.

Managing to Reduce Shatter Losses

- The most important management practice for minimizing soybean yield loss from pod shattering is timely harvest following maturity.

- Soybeans dry very quickly after reaching maturity. At physiological maturity (R7), grain moisture is over 50%, but a harvestable moisture of near 13% can be reached in as little as two weeks under good drying conditions.

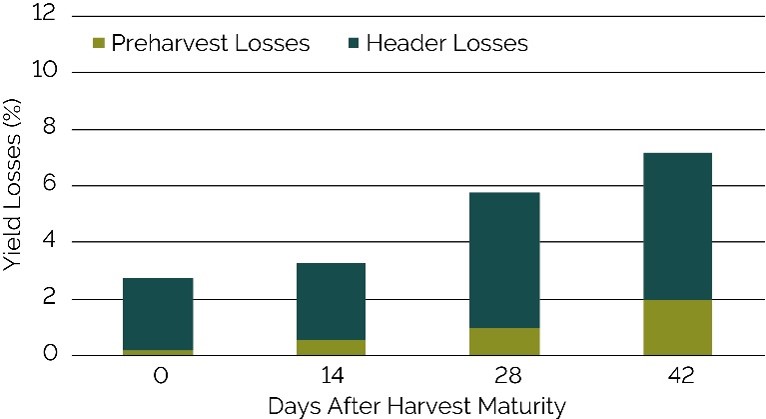

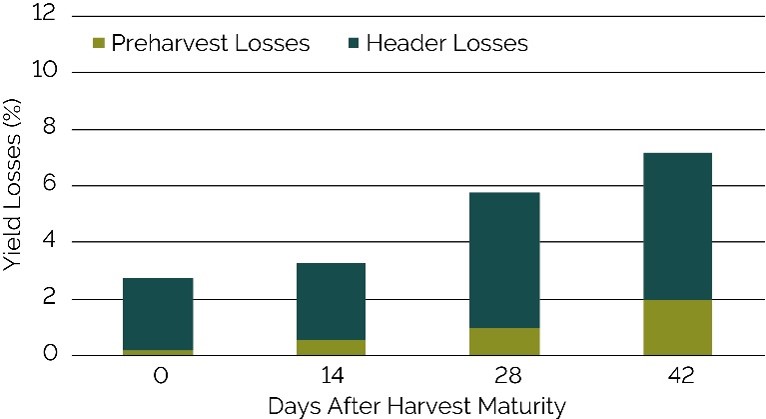

- A University of Wisconsin study showed that yield losses can increase when harvest is delayed more than two weeks after harvest maturity (Figure 3).

Figure 3. Preharvest and header losses associated with delayed soybean harvest (Philbrook and Oplinger, 1989).

- In order to time harvest perfectly, it is necessary to monitor soybean drying very closely. At full maturity (R8), 95% of pods have reached their mature pod color. From this point, only five to ten good drying days are needed before harvest.

Variety Selection

- Timely harvest begins with variety selection – planting varieties with a range of relative maturities can help align maturity with harvest and make sure fields do not reach maturity too far ahead of when they can be harvested.

- Each major soybean maturity group is subdivided into ten relative maturity ratings. Each 1/10 subdivision corresponds to roughly one additional day to reach full maturity – for example, a 2.5 variety will reach maturity approximately 4 days after a 2.1 variety.

- The optimum maturity range for a given operation will depend on length of time harvest typically takes.

- Consult your Pioneer sales professional for recommenda-tions on maturity range and specific varieties suited to your operation.

Combine Speed and Settings

- Slowing down harvest speed can help reduce gathering losses. Keep forward speed at about 3 miles per hour for most combines. Slow down for uneven soil surface or other abnormal conditions.

- Equipment must be properly adjusted and carefully operated to minimize losses. Soybeans that never get inside the combine can account for 80 to 85% of harvest losses.

- Be sure knife sections and ledger plates are sharp, and that wear plates, hold-down clips, and guards are properly adjusted. Chains and bearings should be properly lubricated, and belts tight.

- Proper reel speed in relation to ground speed will reduce gathering losses. Shatter increases if the reel turns too fast; stalks may be dropped if the reel turns too slow. Use a reel speed about 25% faster than ground speed.

- The reel axle should be 6 to 12 inches ahead of the sickle in most cases. Operate a bat reel just low enough to tip cut stalks onto the platform. The tips of the fingers on a pickup reel should clear the cutterbar by about 2 inches.

References

Bara N., D. Khare, and A.N. Srivastava. 2013. Studies on the factors affecting pod shattering in soybean. Indian J. Genet. 73:270-277.

Carpenter, J.A. and W.R. Fehr. 1986. Genetic variability for desirable agronomic traits in populations containing Glycine soja germplasm. Crop Sci. 26:681-686.

Caviness C.E. 1969. Heritability of pod dehiscence and its association with some agronomic characters in soybeans. Crop Sci 9: 207-209.

Dong, Y., X. Yang, J. Liu, B.-H. Wang, B.-L. Liu, and Y.-Z. Wang. 2014. Pod shattering resistance associated with domestication is mediated by a NAC gene in soybean. Nature Comm. 5:3352.

Krisnawati, A. and M.M. Adie. 2017. Variability on morphological characters associated with pod shattering resistance in soybean. Biodiversitas 18:73-77.

Ostlie, K. and B. Potter. 2012. Managing two-spotted spider mites on soybeans. Univ. of Minn. Extension. https://www.extension.umn.edu/agriculture/soybean/pest/managing-two-spotted-spider-mites-on-soybeans/

Philbrook, B.D. and E.S. Oplinger. 1989. Soybean field losses as influenced by harvest delays. Agron. J. 81:251-258.

Tukamuhabwa P., K.E. Dashiell, P.R. Rubaihayo, and E. Adipala. 2000. Inheritance of resistance to pod shattering in soybean. Afr. Crop Sci. J. 8:203-211.

The foregoing is provided for informational use only. Please contact your Pioneer sales professional for information and suggestions specific to your operation. Product performance is variable and depends on many factors such as moisture and heat stress, soil type, management practices and environmental stress as well as disease and pest pressures. Individual results may vary.