Row Width in Soybean Production

Written by Mark Jeschke, Ph.D.¹ and Nanticha Lutt²

Written by Mark Jeschke, Ph.D.¹ and Nanticha Lutt²

Row width is one of the management practices most often considered by growers as potentially important to increased soybean yields and profits. For that reason, numerous research studies have been conducted over the last 40 years to determine optimal soybean row spacing. In general, studies have found that soybean yield potential is often greater with row spacings narrower than 30 inches. Despite these results, narrow-row soybean adoption has varied widely across North America. This Crop Insights reviews research results, current row spacing trends, and factors beyond yield potential that may influence row spacing preferences of soybean growers.

Extensive research studies conducted over many locations and years have compared drilled narrow rows vs. 30-inch rows in soybeans, and have generally shown a significant yield advantage for drilled narrow rows. A compilation of these studies by Purdue University researchers in 2003 showed an average 6.2 bu/acre yield advantage for drilled soybeans (Lambert and Lowenberg-DeBoer). In recent years, however, drilled soybeans have fallen out of favor in many areas, likely due to inferior seed placement and singulation capabilities of drills vs. planters, and the cost of planting additional seeds.

As a result, soybeans planted in 15-inch rows have gained in popularity as a way to capture some of the yield benefit of drilled narrow rows while using a planter instead of a drill. Research on soybeans in 15-inch rows is less extensive, having been conducted mostly within the last 10 to 15 years as this row spacing has gained popularity.

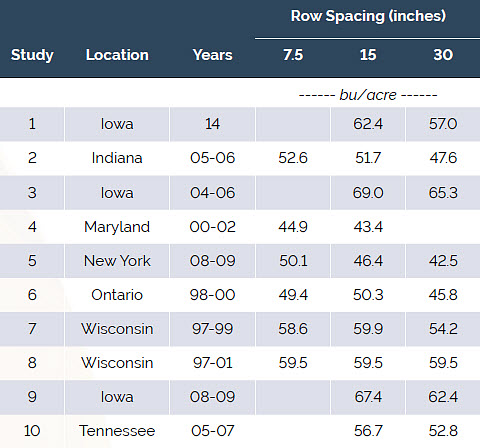

A review of soybean row spacing studies published within the past 10 years generally confirms previous results comparing 30-inch rows and drilled narrow rows. In five studies, drilled soybeans outyielded 30-inch row soybeans by an average of 4.1 bu/acre (Figure 1, Table 1). Nine studies that compared 30-inch rows and 15-inch rows found similar results, with 15-inch rows holding a 4.0 bu/acre yield advantage. Yields were similar between 15-inch row and drilled narrow-row soybeans in these studies.

Figure 1. Average yield results from ten soybean row spacing studies published during the last 15 years.

Table 1. Locations, years, row spacings, and average yields of soybean row spacing studies summarized in Figure 1.

|

1: Hanna et al., 2008; 2: De Bruin and Pedersen, 2008; 3: Kratchovil et al., 2004; 4: Cox and Cherney, 2011; 5: Janovicek et al., 2006; 6: Bertram and Pedersen, 2004; 7: Pedersen and Lauer, 2003.

Because many of these studies used higher seeding rates with narrower row spacings, increased seed costs partially offset the yield benefit associated with narrow rows. Higher seeding rates with narrower rows have been a common practice, particularly with drilled soybean; however, not all research supports this practice. A study conducted in 2008-2009 (Cox and Cherney, 2011) found no row spacing by seeding rate interaction for soybeans planted in 7.5-inch, 15- inch, and 30-inch spacings. Recent research conducted in Iowa had similar results, indicating that narrow-row systems do not necessarily require a greater harvest stand to maximize yield (Pedersen, 2008). Historically, less accurate seed placement made higher seeding rates necessary with drills; however, improved seed placement with newer precision drills has reduced this need. In light of these findings, seed cost may not be a requisite consideration for row spacing decisions.

Conditions favoring narrow rows

Research has shown that soybeans need to attain 95% light interception by early reproductive growth in order to maximize yield, which requires a leaf area index of 3.5 to 4.0 (Board and Harville, 1992). Narrower rows spacings are likely to provide a greater yield benefit in systems where soybeans have a limited time frame for vegetative growth prior to flowering. Such scenarios include northern soybean producing regions where the growing season is shorter (Lee, 2006), early soybean production systems where short maturity varieties are planted early to avoid drought (Holshouser and Whittaker, 2002), delayed planting situations (Lee, 2006), and double-crop systems (Minor and Wiebold, 1998; Holshouser et al., 2006).

Conditions that may not favor narrow rows

Research has also shown that narrow rows may have reduced or no yield advantage under some conditions. Several experiments over the years have shown that moisture stress can reduce the yield benefit of narrow rows (DeBruin and Pedersen, 2008). Brown stem rot, white mold, nitrogen stress, soybean cyst nematode, and Sudden death syndrome may also tend to negate the benefit of narrow rows (Cooper and Jeffers, 1984; Pedersen and Lauer, 2003; Swoboda et al., 2011).

Row spacing research in corn has generally shown that the yield advantage with narrow rows diminishes outside of northern Corn Belt latitudes, since corn grown in the central Corn Belt and south is better able to attain maximum light interception prior to flowering (Butzen and Paszkiewicz, 2008). No such trend has been consistently observed in soybean when planting at optimum timings, although narrow rows have proven advantageous with late planting regardless of latitude (Lee, 2006).

In recent years, 15-inch and 30-inch row spacings have been the most common planting configurations in North American production, each accounting for over 1/3 of total acreage (Figure 2). Drilled soybeans, in row spacings of 12 inches or less, account for less than 20% of total acreage.

Figure 2. Soybean row spacings (in inches) in North America as a percentage of total acres, average 2011-2015. Source: 2015 Pioneer Brand Concentration Survey.

However, row spacing practices vary widely across different areas. Among the largest soybean-producing states there are substantial differences in row spacing practices, with a majority of growers in Illinois, Indiana, Ohio, and Missouri favoring 15-inch spacings, compared to Iowa and Minnesota where soybeans planted in 30-inch rows are much more common (Figure 3). Row spacings of 36 inches and wider are rare in the northern and central Corn Belt, but more common in southern raised-bed systems. Similarly, 22-inch rows are common in sugar beet producing areas such as Minnesota, but are not generally found elsewhere.

Figure 3. Soybean row spacings (in inches) in the largest soybean-producing states in 2015 as a percent of total acres (USDA-NASS, 2015 Crop Production Survey).

One consistent trend across North America over the last several years has been the move away from drilled soybeans. Drilled soybeans have declined from 20% of soybean acres in 2011 to 14% in 2015 (Figure 4). Even in areas such as Eastern Canada and the Northeastern U.S. where drilled narrow rows is still the most common soybean row configuration, drilled acreage has dropped over the last five years. Planters generally provide better seed placement and seedling emergence than drills, which has helped reduce seeding rates and associated costs, although improvements in seed placement with newer drills make this less of an issue than it has been in the past (Holshouser et al., 2006).

Figure 4. Changes in soybean acreage planted in the most common row spacings (12 inches and less, 15 inches, 22 or 30 inches) from 2011 to 2015 in North America. Source: 2015 Pioneer Brand Concentration Survey.

In many cases, this decline in drilled soybeans has been accompanied by an increase in acres planted to 15-inch rows, which is now the most common row spacing for soybean. However, acreage planted to 30-inch rows has also increased in almost all regions of North America over the last several years, reversing the long-term trend away from wider rows. In some areas this increase has been substantial. For example, Illinois went from 18% to 32% of soybean acres planted to 30-inch rows over the last ten years (USDA-NASS survey). This recent shift toward wider row spacings runs counter to the higher yields often associated with narrower rows, which indicates that other factors beyond yield are driving grower decisions in this area.

Equipment and Time Management

Other than yield, the most important factor driving soybean row spacing practices is equipment and time management during the planting season. One of the key issues growers must consider is whether the economics of their farm justify having a machine dedicated specifically to planting soybeans.

Larger farms are more able to justify the expense of a dedicated soybean planter and provide an operator for it. Thus, they are more likely to be planting soybeans in 15-inch rows (Figure 5). For smaller farms, it may be more practical to share a soybean planter with another crop, such as a drill with wheat or a 30-inch planter with corn. This often results in more 30-inch or drilled soybeans for smaller farms (Figure 5).

Figure 5. Soybean row spacing utilization according to farm size in 2015 (Small = 1-99 soybean acres, medium = 250-499 soybean acres, large = 500+ soybean acres). Source: 2015 Pioneer Brand Concentration Survey.

As farms get larger, more acres must be planted in a shorter amount of time. Wet conditions in many areas during the last few planting seasons have exacerbated this situation by creating very short and intermittent planting windows. To plant more acres during the available window, some growers have opted to use their 30-inch planter for soybeans. Because 30-inch planters are typically wider than 15-inch planters, they can cover the ground more quickly. Another option – owning a second planter specifically for soybeans – allows both crops to be planted at the same time, resulting in earlier completion of soybean planting. However, the total number of operator hours spent planting would be greater and the second planter would require a second operator, which may not always be feasible.

It is difficult to weigh the potential yield benefit of narrow-row soybeans against equipment costs, time constraints and operator availability required. Equipment and workload considerations are unique for every farm operation and ultimately come down to the needs of each individual grower.

White Mold

A factor that has likely played a role in the recent increase in soybeans planted in 30-inch rows in some areas is Sclerotinia stem rot (Sclerotinia sclerotiorum), or white mold. White mold development is favored by cool and wet conditions during soybean flowering. A dense soybean canopy can enhance these conditions and increase white mold severity. The rationale behind increasing row spacing is to increase light penetration and air movement in the lower canopy, thereby making conditions less favorable for white mold development.

Soybean variety selection, row spacing and seeding rate are important factors influencing white mold development and a good management strategy should address all three. Seeding rate generally appears to have a greater effect on white mold severity than row spacing (Lee et al., 2005). Changing from drilled narrow-row soybeans to 15-inch row spacing in areas where white mold is prevalent is likely a good move, particularly when accompanied by a reduction in seeding rate. The benefit of moving to a 30-inch spacing is less clear and is not generally recommended by university pathologists for reducing white mold, particularly given the likely reduction in yield potential. However, in areas with frequent white mold incidence, wide rows may provide some benefit.

Foliar Fungicide and Insecticide Applications

The need for fungicide and/or insecticide applications may also impact row spacing decisions. When an application is made during vegetative growth, plants are generally able to compensate for damage caused by the sprayer wheels with little reduction in yield. For applications made following the R1 growth stage, which would include most foliar fungicide and insecticide applications, wheel damaged areas will have lower yield. A research study conducted in Delaware and Virginia found significant yield reductions due to sprayer wheel damage in R4 soybeans planted in 7.5-inch and 15-inch row spacings, whereas soybeans planted in 30-inch and wider row spacings did not sustain any sprayer wheel damage (Holshouser and Taylor, 2008). Actual yield loss due to wheel traffic will vary according to boom width (Table 2).

Table 2. Soybean yield loss due to sprayer wheel damage in 7.5-inch and 15-inch row spacings with four different boom widths (Holshouser and Taylor, 2008).

Although 30-inch rows would generally be expected to allow sprayer wheels to pass through without damage, wheel traffic damage may not always be negligible. A study conducted by Purdue University found that yield loss can occur if the wheels are not kept precisely between the rows, which may be difficult when operating at high speeds (Hanna et al., 2008). Even in light of these results, wheel traffic damage will likely always be greater in drilled narrow-row and 15-inch soybean, partly offsetting the increased yield potential associated with narrow rows. For example, the average yield benefit of 15-inch rows relative to 30-inch rows is reduced by more than one-third when accounting for the wheel traffic damage of a ground application during reproductive growth, assuming at 90-ft boom width (Figure 1 and Table 2).

Because fungicides are only locally systemic and are not translocated from upper to lower portions of the canopy, spray coverage is critical for maximum efficacy. For that reason, it is important to consider the effect of row spacing on spray coverage. Purdue University research found that spray penetration into the lower canopy was similar among soybeans planted in 7.5, 15, and 30-inch row spacings and that a minimum carrier volume of 15 GPA was more important to maximizing spray coverage (Hanna et al., 2008) than was row spacing.

Weed Control

The growing prevalence of weed populations resistant to glyphosate has made weed management more challenging in some areas; consequently, it is becoming increasingly necessary to consider the impact of cropping system factors such as row spacing on weed growth. In general, weed growth will be reduced in soybeans planted in narrower row spacings and earlier shading by the soybean canopy will help suppress the emergence of new weeds. The extent of this effect will vary by weed species and weed emergence timing relative to the crop (Hock et al., 2006).

Planting and Harvest Efficiency

Crop residue can be an important consideration when planting soybeans, particularly in the northern Corn Belt where residue management is more of a challenge. Some growers in high residue systems prefer wider rows because there is more room to deposit residue between the rows, which helps prevent residue interference with planting and emergence. Narrow-row soybeans offer some harvestability advantages over soybeans in 30-inch rows. The lowest pods will tend to be higher in narrow-row soybeans, potentially reducing harvest losses. The more even distribution of plants in narrow rows also allows plants to feed into the combine head more smoothly, although some growers have found that harvesting 30-inch row soybeans at an angle can help improve harvestability.

Recent research studies have around a 4 bu/acre yield advantage for soybeans planted in drilled narrow rows or 15-inch rows compared to 30-inch rows. In spite of this advantage, row spacing preferences vary greatly across North America, and 30-inch row soybeans are common and reflect a shift in planting attitudes. This demonstrates that many different considerations beyond simply yield potential can affect the best practices for each individual grower. Factors such as equipment costs, workload management, and disease management all play an important role. When those issues are accounted for, narrow-row planting is not necessarily the best economic choice for all operations. Because of this complexity, no one-size-fits-all answer should be applied. Rather, each grower should carefully consider the costs, risks and benefits of soybean row spacing options in their farming operation.

¹Mark Jeschke, Ph.D., Pioneer Agronomy Information Manager

²Nanticha Lutt, Pioneer Agronomy Sciences Intern

When you choose to grow soybeans with us, you are backed by the power of Pioneer: more data points, a faster research pipeline and industry-leading field teams.

See the Power