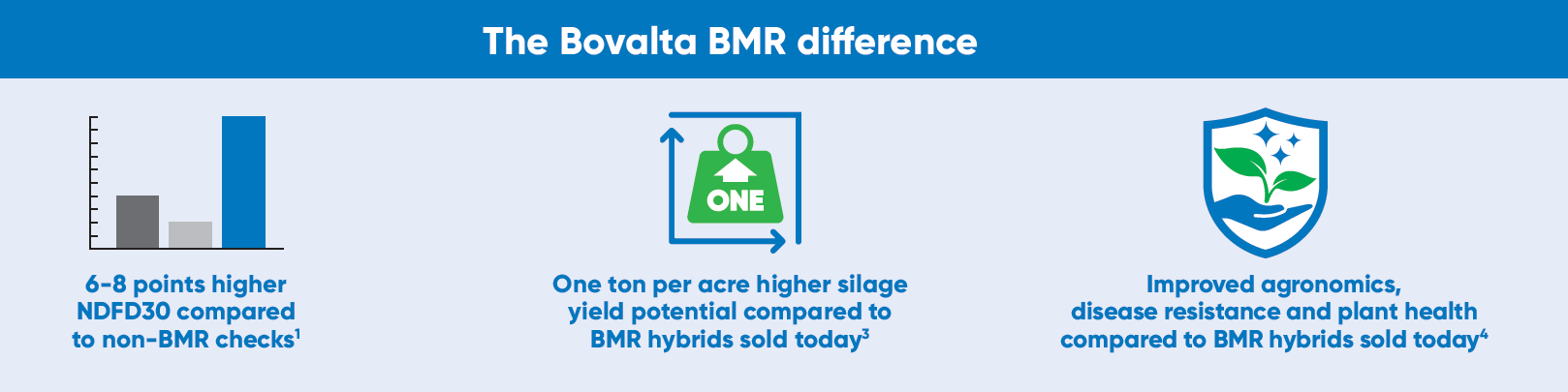

Meet BMR hybrids that are the product of Corteva Agriscience’s extensive research and testing network. They have earned the highest standard for digestibility and milk production and demonstrate outstanding performance in yield, disease resistance and agronomics. With 6-8 points higher NDFD30 compared to non-BMR checks and one ton per acre higher silage yield potential compared to BMR hybrids sold today1,3.

Bovalta® BMR Corn Silage Products

Taking BMR to a new level of silage performance, agronomics and profit.

Three Key Differences with Bovalta® BMR

1. Highest standard for digestibility & milk production1,2

- 6-8 points higher NDFD30 compared to non-BMR checks

- Highly digestible, high energy corn silage can lead to:

- Lower dietary undigestible fiber (uNDF240) allowing for higher corn silage inclusion levels

- Lower supplemental feed costs

- Improved dry matter intake

- Potential for higher milk yields

2. Higher standard for yield, disease resistance & agronomics3,4

- Tested in a range of environmental conditions, hybrids must meet outstanding criteria for:

- Yield/tonnage

- Bovalta BMR hybrids are selected as the best-of-the-best for tonnage

- One ton per acre higher silage yield potential compared to BMR hybrids sold today

- Agronomics

- Bovalta BMR hybrids have improved leaf disease protection for better yield potential

- Selected for improved standability and roots

- Yield/tonnage

3. Higher standard for on-farm business impact.

- Enhanced revenue and profit potential

- Greater milk yield potential - more revenue

- High fiber digestibility - greater forage intake potential

- Additional tonnage potential - lower input costs

Contact

My Local Pioneer Team

Our unmatched team of local professionals live and work in your community. They’re ready to help you select products with superior yield potential and provide year-round service and expertise. Have questions? Ask your local Pioneer sales representative today.

Find My Local Team

1Corteva Agriscience. Research studies of NDFD. Data on file, 2021.

2Gencoglu, Hidir, Joe Lauer, and Randy Shaver. "Brown Midrib Corn Silage for Lactating Dairy Cows: A Contemporary Review." University of Wisconsin-Madison, Departments of Dairy Science and Agronomy, January 2008.

3Corteva Agriscience. Comparisons of BMR corn hybrid yield. Data on file, 2021.

4Corteva Agriscience. Comparisons of disease resistance ratings. Data on file, 2021.

5Cherney, Jerry, Bill Cox, and Debbie J.R. Cherney. “Feeding BMR Corn Silage.” Grass Information Sheet Series Information Sheet 33. Cornell University Cooperative Extension, Field Crops Extension, 2011.