From planting through storage and feeding, the Silage Zone® Resource is your one-stop source for each stage of forage production. Get cutting-edge management tips straight from the global Pioneer team of agronomists and nutritionists.

The Silage Zone® Resource Center

Feed for Thought

A webinar series where Pioneer experts break down the most important topics in forages management.

Watch the SeriesManagement Resources for Your Operation

The Silage Zone® Resource has management tips for every forage crop and each stage of forage production. Find specific resources to improve your feeding routine.

Corn Silage Management

Pioneer knows every aspect of corn silage production. Get the advice you need to select the best Pioneer® brand products, control local pests, harvest in the right conditions and retain nutrients to make the most of your crop.

Alfalfa Management

We’re here to help with everything from field-by-field variety recommendations to improving bunker management. Our full-season agronomic advice includes stand assessments, disease control and insect management considerations. Our resources improve your productivity from planting to feeding.

Inoculants Management

From harvest through feeding, maximize your silage value with management tips for using Pioneer® brand crop-specific inoculants to get more from every acre you feed.

Silage Staging Tool from Granular Insights

Get support from your local team and Granular this harvest season. Develop a plan for when to start, and what hybrids to start with, avoid harvest bottlenecks and have insight to when you could have a potential harvest gap. Reach out to your Pioneer Sales Representative to get started.

Featured Articles From the Zone

Improve your forage program with timely in-season resources from the Pioneer agronomy and nutrition team.

Silage Stories

Real stories, valuable advice. See how other farmers are working with their team of Pioneer nutritionists and agronomists to increase production and improve management in their operations.

Feltz Family Farms, Wisconsin

This 100-year-old dairy looks to the future with robots, cow comfort and Pioneer® brand corn silage.

Read Story

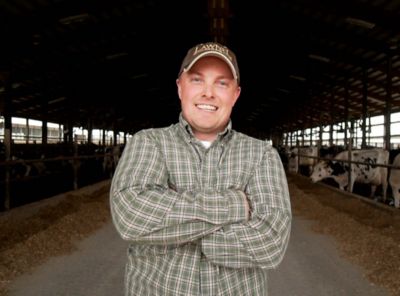

Lawnel Farms, New York

An award-winning farm of 3,500 cows and 3,000 acres of silage started with one borrowed cow in 1945.

Read Story

Kasper Dairy, Idaho

Varied climate and diverse elevations contribute to this dairy’s complex rotation schedules.

Read StoryWe Know Dairy

Specialized Dairy Advice

Pioneer is the industry leader that connects farmers to local agronomic solutions. Explore our agronomy library for more information.

All Dairy Articles