By Bill Mahanna

Grain yield and kernel test weight are typical parts of the cafe discussion around hybrid selection in the winter or corn harvest in the fall. Test weight also factors into the price at the elevator when discounts are applied for delivered grain that weighs less than 56 lb./bu. While the terms bushels and test weight are bantered around, it might be worthwhile to dig into these terms and compare their importance at the elevator compared to the feed mill (or total mixed ration mixer).

Bushels, test weight

The bushel is a volume measurement to facilitate fair grain trade that traces its roots back to the year 871 when King Alfred the Great chose Winchester in southeastern England as the capital of his kingdom of Wessex. The earliest surviving bushel is a 1497 bronze vessel from the reign of Henry VII (Connor, 1987).

Two hundred years later, in preparation for a new tax on malt, members of Parliament measured the capacity of a Henry VII standard bushel as 2,145.6 cu. in. To facilitate the rapid manufacture of the new measures, the dimensions were rounded off to 18.5 in. in diameter by 8.0 in. high. Britain abolished the Winchester bushel in 1824, but the "simplified" bushel concept survived and become the basis of the bushel used today in the U.S. (Connor, 1987).

The bushel has a volume of 1.244 cu. ft. (typically rounded to 1.25 cu. ft.) or the amount of grain to level fill a quart container (32 qt./bu.). Although trade is based on bushels in the U.S., the rest of the world trades on the basis of weight (typically metric tons).

To facilitate the trading of grain, the U.S. Department of Agriculture created weight standards for each grain so it could be weighed to determine the number of bushels rather than trying to make volume measurements. Corn was assigned a bushel weight of 56 lb., with soybeans and wheat assigned bushel weights of 60 lb.

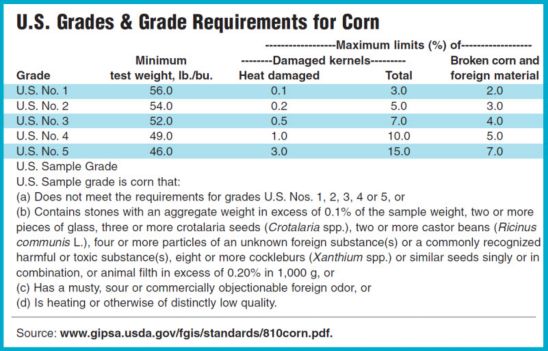

Test weight is a measure of bulk density or the quantity (pounds) of grain to fill a specific volume (bushel). Test weight is part of the official U.S. standards for grain trading (Table) and one of the common tests employed by food processors and seed companies as a proxy for endosperm hardness when evaluating hybrids for food uses such as corn chips or tortillas.

The official USDA Federal Grain Inspection Service method uses grain at between 12% and 16% moisture and involves filling a quart cup (kettle) through a gated hopper (funnel), positioned at a specific height above the cup, to the point where grain begins to pour over the sides of the test cup. A strike-off stick is used to level the grain in the quart cup, and the grain remaining in the cup is weighed (Bern and Brumm, 2009). The grain weight in the cup is then converted to weight per Winchester bushel and reported as pounds per bushel.

Moisture content of the sample is also reported because test weight increases with kernel dry-down (moisture loss) due to dry matter being concentrated. There are other unofficial methods to estimate test weight in the field or at the elevator, and their use in trade is regulated by individual states (Nielsen, 2011).

True density is a more direct measurement of endosperm hardness and is calculated by dividing the weight of 100 externally sound kernels by the volume of the same 100 kernels determined using a helium pycnometer. This laboratory method reports grams per cubic centimeter (typical range is 125-1.35 g/cc), 100 kernel weight (typical range is 25-40 g) and average kernel volume (typical range is 20-28 cc).

Test weight and true density are somewhat correlated with more floury genetics typically having lower test weight and density. However, only about 40% of the variation in grain density can be attributed to variation in test weight due to influences of kernel size, shape, maturity, germ content and pericarp slickness on the official "hopper-quart cup" test weight method.

Low test weight causes

Test weight helps account for the varying densities of grain caused by weather and/or production practices. There are a number of causes of reduced kernel fill including hybrid genetics, low temperatures, reduced solar radiation (cloudy conditions), premature death due to leaf disease, ear rots (such as Fusarium, Gibberella and Diplodia), drought, freeze damage to late-developing fields (Antos, 2011).

When kernels are prevented from filling completely and/or maturing and drying naturally in the field, the starch molecules inside the grain are prevented from the natural process of shedding absorbed water molecules that allows the grain to shrink to a normal size. Artificial drying with heat removes this excess water but the starch molecules do not shrink and grain size doesn't change appreciably, so test weight remains relatively low.

In some situations, mature kernels significantly hydrated by rain, dew or fog can initiate precocious germination in the field during which starch is utilized for energy leaving small voids inside the grain. Although the grain may again dry in the field, the seed size does not change, and the small voids inside the seed can result in a decreased test weight (Beuerlein, 2012).

Test weight for a given hybrid can vary from field to field and from year to year and does not correspond very well to the yield potential of the environment. Data from Purdue University shows the lack of correlation between grain yield and test weight in nitrogen rate trials over multiple site-years in Indiana.

Transportation, storage

At the elevator, 1 bu. of corn is defined as 56 lb. independent of test weight. The weight of the corn for which a seller is paid is, therefore, not affected by test weight - 56 lb. is 56 lb.

However, the price the seller receives for a bushel can be affected by test weight. Transporting and storing lower bulk-density grain is more costly (on a weight basis), so buyers discount grain on a sliding scale if test weight is below minimum standards.

Higher weight per unit volume of grain has obvious advantages in harvest, handling and storage: More bushels will fit in the combine grain tank, on a truck or in a grain bin.

Consider 80 acres of a high-test hybrid (58 lb./bu.) versus a lower-test hybrid (52 lb./bu.). In a given volume, 11% more of the higher-test hybrid can be held (58- 52=6/52=0.11). Assuming a semitrailer would hold about 900 bu. with the lower test hybrid and 11% more, or 1,065 bu. for the higher-test corn.

If the higher-test hybrid yielded 200 bu. per acre, it would fill 15 semi loads (200 bu. per acre x 80 acres = 16,000 bu.; 16,000 bu./1,065 bu. per semi load = 15 semi loads). The same weight of corn for the low-test hybrid would require 18 semi-loads to haul the grain (16,000 bu./900 bu. per semi load = 17.8 semi loads; Antos, 2011).

Furthermore, in this example, the higher- test hybrid will occupy 11% less space in the combine grain tank leading to an erroneous assumption that the higher test hybrid was lower yielding.

Grain drying

Kernel moisture and test weight are inversely related with higher moisture kernels displaying lower test weight. As corn dries in the field or in a dryer, test weight naturally increases as long as kernel integrity remains intact. Test weight increases because dried kernels shrink and are slicker so tend to pack more tightly in a quart cup. Kernels are also denser (specific gravity at 0% moisture about 1.5) than water (specific gravity is 1.0), so bulk density goes up as water exits the kernel (Bern and Brumm, 2009).

While it is true that test weight will increase due to natural or artificial drying, the increased test weight means the corn will occupy less total volume because of increasing the corn bulk density and could potentially reduce test weight dockage at the elevator. It does not mean there will be any more bushels (pounds) to sell because 1 bu. is 56 lb. regardless of test weight.

When the growing season produces low-test corn, it is important to feed corn based on weight and nutrient content and not volume such as bucket loads (Bern and Brumm, 2009).

Livestock considerations

Research on feeding light-test weight corn to dairy cattle is lacking. However, there is a considerable body of research from beef cattle showing that moderately low-test corn (46-48 lb./bu.) results in similar daily gain and feed efficiency to normal corn (Weichenthal et al., 1998; Birkelo et al., 1994). This supports an early study from Minnesota (Thornton et al., 1969) showing very little difference in the gross energy of corn ranging from 35 lb. to 56 lb./bu.

Due to a lowered starch dilution effect, light-test corn will be higher in crude protein and fiber, so analyzing nutrient content and using modern summative net energy equations may be the best way to determine feeding rates (Shaver and Hoffman, 2003).

Growing seasons that result in low-test corn may also predispose the crop to mold and mycotoxin problems.

Some beef studies (Birkelo et al., 1994) have actually reported higher net energy for maintenance and for gain for lighter test weight corns (41 lb./bu.). Part of the explanation may lie in the fact that nutrient density does not predict nutrient rate of digestibility. Research in the Netherlands at the Nutreco Ruminant Research Centre indicates that while lighter-test corn has less endosperm, the starch that is present may be more rapidly digested in the rumen (Woodley, 2009). This could have important implications for maintaining fat test in dairy diets.

The final watch-out with potentially reduced kernel size is paying close attention to processing to be sure particle size or flake weight is consistent. Research across hybrids suggests that larger kernels may lead to improved total tract organic matter digestibility when corn grain is fed in either the dry-rolled, fl aked or high-moisture form. This may be partly because larger kernels have a greater ratio of starch to pericarp (fiber).

Field experience indicates that when dry corn is rolled, larger kernels result in more uniform and complete processing. In a Nebraska study (Jaeger et al., 2004), seven hybrids were dry rolled and fed to steers. Average daily gain did not differ among hybrids but feed efficiency was superior for hybrids with a larger mean kernel weight. Some nutritionists have suggested a minimum of 35 g per 100 kernels as a proxy physical measurement for ensuring larger kernel size (Soderlund, 2009).

The Bottom Line

Research supports the sage advice of selling high-test weight corn and feeding low-test corn. While test weight, a measure of grain bulk density, has important implications for pricing at the elevator and transportation/storage costs, it has less significance for feeding the grain to ruminants.

The primary watch-outs for feeding light-test corn include a tendency for faster ruminal starch digestion rates, monitoring for mycotoxin levels, the need to feed by weight not volume and close attention to processing consistency.

References

Antos, Matt. 2011. Personal communications. Pioneer Agronomist.

Bern, C., and T.J. Brumm. 2009. Grain Test Weight Deception. Iowa State University Extension.

Beuerlein, J. 2012. Bushels, test weights and calculations. Ohio State University Bulletin AGF-503-00.

Birkelo, C.P., R.H. Pritchard, M. Buhman, S. Grosch and C. Willms. 1994. Net energy of finishing diets containing light or normal test weight corn. South Dakota State Univ. Beef Report. 94:2.

Connor, R.D. 1987. The weights and measures of England.

Jaeger, S.L., C.N. Macken, G.E. Erickson, T.J. Klopfenstein, W.A. Fithian and D.S. Jackson. 2004. The influence of corn kernel traits on feedlot cattle performance. University of Nebraska. 2005 Beef Cattle Report, p. 54-57.

Nielsen, R.L. 2011. Test Weight Issues in Corn. Corny News Network. Purdue University Department of Agronomy.

Shaver, R., P. Hoffman and J. Lauer. 2003. Dairy cattle feeding tips for drought stressed corn. University of Wisconsin Extension.

Soderlund, S. 2007. Personal communication. Pioneer Hi-Bred Beef Nutritionist.

Thornton, J.H., R.D. Goodrich and J.C. Meiske. 1969. Corn maturity. I. Composition of corn grain of various maturities and test weights. J. Anim. Sci. 29:977.

Weichenthal, B.A., I.G. Rush and B.G. Van Pelt. 1998. Light-test weight corn from growing and finishing steers. The Professional Animal Scientist 14:114-117.

Woodley, B. 2009. Feeding corn to dairy cattle.

This article was originally published in June 2012 Feedstuffs issue, and is reproduced with their permission.