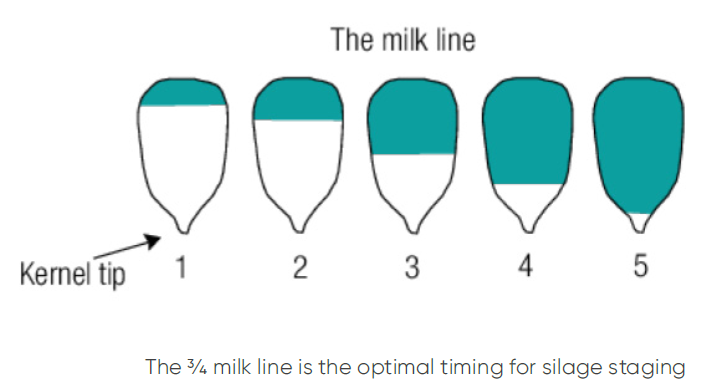

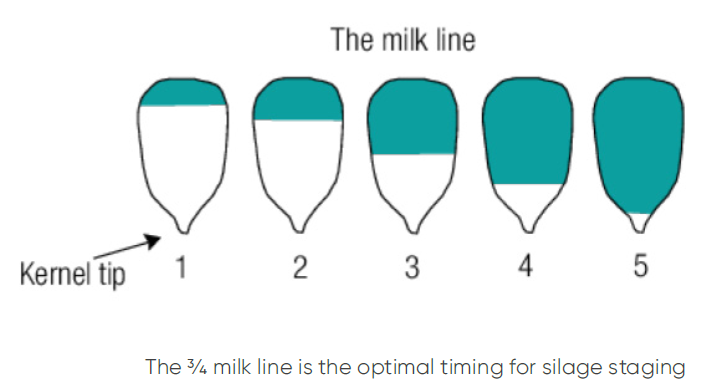

One of the most important decisions in corn silage production is optimal harvest timing. This means finding the best balance between maximum kernel maturity and overall plant health to maintain fiber digestibility and moisture for packing and fermentation of the silage. Typically, this will be achieved at ¾ milk line in healthy plants and ½ milk line for unhealthy ones. Regardless, it involves getting into the field to assess both.

1. R3 Milk Stage: Crop is green and actively growing.

- Corn plants towards the outside of the field can mature faster than those further into the field, so go in a few rows to pull an ear from a plant that best represents the overall field maturity

- Shuck the corn ear paying attention to kernel colour (yellowing) and potential denting

- Break the ear in half and examine the core of the top half to see if a starch line is present

- Heavily liquid, lack of denting, softer kernels and no starch line indicate the crop is far from maturity

2. R5 Dent Stage. Crop is still green but does not show signs of active growth.

- Repeat the process from the previous stage

- Look for grain denting, a sign that starch is now present (and developing)

- Examining the radius of the broken ear should now reveal the development of a starch line within the kernels

- Check the milk line and test for uniform grain firmness

- Kernels that are softer and milkier with liquid towards the tip of the kernel are still a couple weeks away from harvest

3. ½ Milk Line. Visually the crop has entered dry down, plant moisture is decreasing, and grain fill has slowed down.

- Husks are noticeably drying-off

- Repeat previous steps

- Look for heavier denting and a milk line that has moved closer to the core of the ear (a good sign that the kernel is filling with starch)

- Cut or break apart a kernel to see the development of hard starch within

- 40% grain moisture with whole Plant dry matter between 40 – 45%

- Although this stage does not represent the peak of fiber digestibility, it is the optimal harvest timing for unhealthy plants

4. ¾ Milk Line Stage: Crop is almost at full maturity

- Milk line has moved further down

- Grain fill is complete

- Kernel is full of starch

- Increased fiber digestibility can be achieved by chopping higher

- Silage inoculants can also be added as you are chopping to increase dry matter recovery and increase digestibility of the silage

- Target 62-68% whole plant moisture – the key point is to get the moisture in the correct range, too wet or too dry can significantly affect the quality of your silage

- 36% grain moisture with whole Plant dry matter between 35 – 40%

- This is optimal harvest timing for healthy plants