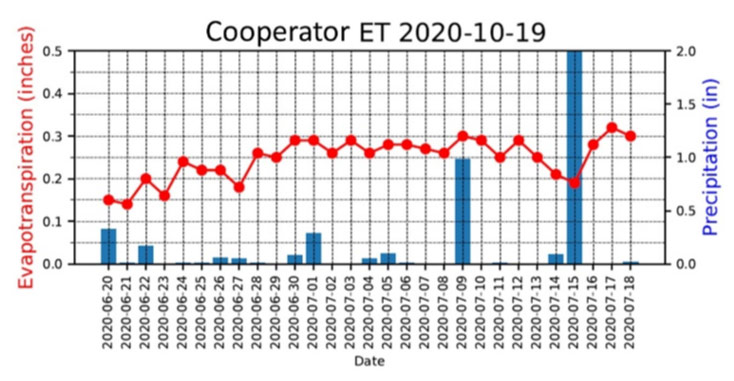

To analyze yield gap at the end of a season, first calculate an estimate of crop evapotranspiration (ET) to determine potential yield. Then you can compare potential yield to actual yield to identify opportunities for closing the gap.

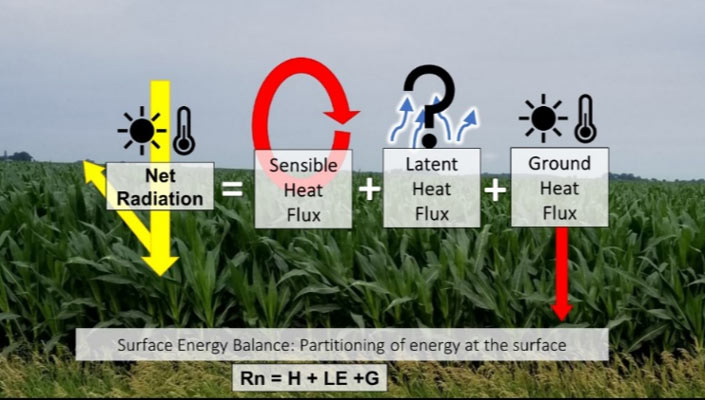

Figure 1. Surface energy budget over corn.

Evapotranspiration is calculated using the energy balance method (Figure 1). The surface energy balance equation used in this project for the crop-soil surface is written as

Rn = H + λE + G

where Rn is net radiation, H is sensible heat flux, λE is latent heat flux and G is the ground heat flux.

Rn, the net radiation, is the absorbed solar and thermal energy from the atmosphere and is balanced by sensible (energy exchange from air movement), latent (energy exchange from transpiration/ evaporation), and ground (energy gained or loss during below ground warming or cooling) heat fluxes.

The Rn and G components of the energy budget can be measured or modeled using meteorological variables measured by basic weather stations (windspeed, air temperature, relative humidity, and incoming solar radiation). The H term is calculated by characterizing the surface temperature fluctuations that are measured by an infrared thermometer (IRT) which is a non-contact thermometer (meaning it is not in direct contact with a plant). The λE term is difficult to quantify using basic and inexpensive sensors and is thus calculated as the residual of the energy balance:

λE = Rn - H - G

Evapotranspiration is then calculated by dividing λE by the latent heat of vaporization (λ) to convert the energy into a volume/depth of water loss.

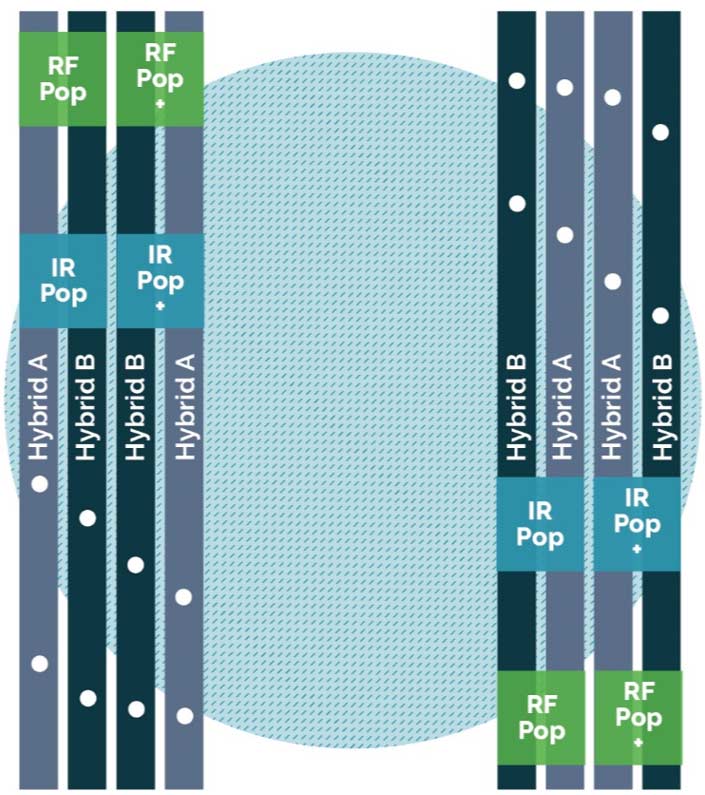

In the 2019 and 2020 seasons, the measurement variables necessary for the energy budget were obtained from weather stations or IBM weather service, and from Corteva Agriscience proprietary Internet of Things (IoT) devices equipped with an infrared thermometer. This IoT device (Figure 2) was designed and manufactured in-house by the Corteva Agriscience Predictive Ag and Engineering teams. The device measures the surface temperature, processes the data, and then sends 30-minute averaged values to a Corteva Agriscience-maintained cloud database using a cellular modem.

Figure 2. IoT device for measuring surface temperature (left) and the device deployed in a field (right).